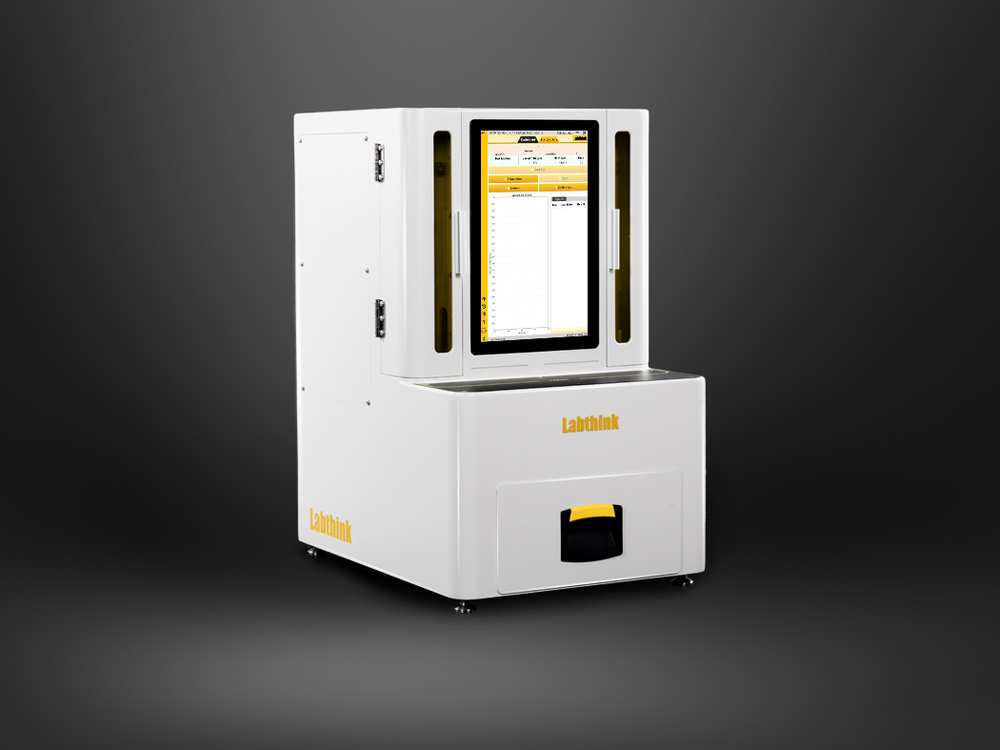

Vials & Eye Drop Bottles CCI Tester

Product Details:

Vials & Eye Drop Bottles CCI Tester Price And Quantity

- 1 Set

- 1 USD ($)/Set

- 5000.00 - 50000.00 USD ($)/Set

Product Description

C690H PACKAGE NON-DESTRUCTIVE LEAK Detector is suitable for package sealing test, This instrument is is based on the testing principle of the vacuum decay method and and completely non-destructive testing technology.

According to ASTM F2338 vacuum attenuation sealing test standard requirements, the instrument is suitable for batch sealing leak detection of vials, and trace leakage detection of ampoule, cartridge bottles, infusion bottles, prefilled syringes and other pharmaceutical packaging

Features

1. can facilitate continuous testing of 20 to 120 samples.

2. A & B dual-channel design can test samples of two different specifications simultaneously

3. Dual methods of vacuum decay and pressure decay

4. Advanced microflow automatic flow control technology

5. Both the differential pressure transducer and flow meter are traceable to NIST.

6. can achieve a higher test repeatability of ±1um.

Technical Features

Container Application: Vials, ampoules, prefilled needles, Injection bottles

Products: Semi-solid, Powder, Lyo, Liquid

Container amount: 20120

Technology: CCIT

Inspection features: Non-Invasive, Non-Destructive CCIT based on Vacuum & Pressure Decay Method

Inspection Capabilities: Microleaks detection

Test Limit: (less than 3um)

Apply Standards

1. Approved industry standard "ASTM F2338-09: "Standard Test Method for Non-Destructive Detection of Leaks in Packages

2. United States Pharmacopoeia “ USP General Chapter «1207» "Packaging Integrity Evaluation

3. FDA 21 CFR Part11

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese